Manufacturing Capabilities

… Loading …

Engineering Design

Eng Design.JPG)

Over 20 years experience design team.

Design and Manufacturing Standards: Relevant ASTM/ISO/JIS /GB documents

A design team of over 20 years experience in products and production.

Soft Ware used : AutoCAD Inventor , PRO-E , Solidworks.

Design and Manufacturing Standards : relevant ASTM/ISO/JIS /GB documents.

We are open to offer our suggestions for product enhancement , sharing technical issues on production processes and potential finishing problems such as plating.

Tool Making

Tool Making 1.jpg)

Full engineering development and in-house tooling support. State-of-the-art tooling equipments.

Experienced team and state-of-the art equipment for building own tooling.

Full engineering design development and in-house tooling support.

Quick tool maintenance for immediate production recoveries.

Sheet Metal Fabrication

Sheet Metal Fabrication.jpg)

Punch Press, 15-35T, 80 sets

Punch Press, 40-110T, 45 sets

Current metal fabrication capacities :

Punch Press , 15-35T , 80 sets

Punch Press , 40-110T , 45 sets

Our set up allow us the ability to manufacture multiple parts of different designs and sizes at any one time.

Progressive Stamping

Progressive Stamping.JPG)

High Speed Stamping Line, 25-45T, 60-300 stroke per minute, 20 sets

For high volume demands , our high speed stamping set up will allow us to provide deliveries within a limited time frame.

Progressive Stamping Press : 25-45T , 60-300 stroke per minute , 20 sets

Turret Punching

20T, 4’X4′, Soft programmable stamping – proto to medium volume

A piece of equipment for building protos at minimum hard tooling and quick turnaround time.

It is a soft programmable stamping press suitable from protos to medium production run.

Turret Capability:

Tonnage and Bed Size: 20T, 4′ X 4′

Stamping Speed: 400 SPM average.

General Tolerances: +/- 0.10 mm

Laser Cutting

Laser Cutting.JPG)

4KW Laser Center, Bed Size 5’X10′, Max Thickness of cut: CRS/Stainless/Aluminium: 22mm / 9mm / 10mm

Versatile and Powerful suitable for protos as well as production.

Can be used as a material saver especially when blank designs are such a way that high material wastage will be resulted with conventional stamping methods.

Our Laser Capability:

Soft programmable suitable for iron, stainless and aluminum sheets.

Machine Specification:

4 KW Output Max, Bed Size 5’X10′; Max thickness of cut: CRS/Stainless/Aluminum: 22mm / 9mm / 10mm

Press Brake

Press Brake 2.JPG)

Sheet Metal Forming. Our press brakes is from 80T, 2500mm wide and multi-stage bending to reduce setup time!

A precision tool to allow multi-stage bending and reduce set up time!

Used on protos and production.

Our Press Brakes:

Soft programmable bending and forming

Machine Specification: 40T, Bend Width 1.3 to 3.0 Meter Max.

Precision CNC Machining

Precision CNC Machnie 2.JPG)

High precision machining to your exact requirements.

Base Material Suitability : Aluminum and Zinc Alloys , CRS Steel , Stainless Steel , Brass or Copper.

Machine Type : Soft programmable CNC Milling and Tapping Centre , 16000 RPM , 14 Tools , Bed Size 360 x 430 mm

Machined Tolerances : General +/- 0.002″ (+/- 0.05 mm) ; Controlled +/- 0.0012″ (+/- 0.03 mm) , CPK Statistical Model monitored.

Production Capacity : 28 Sets , Single or Full Shift.

Typical Products : Custom panels , cPCI Panels and ejectors , heat sinks.

Welding — Spot, TIG & 3D

Welding-Spot , TIG & 3D.jpg)

Conventional Spot welding, Inert Gas Welding and 3D Orbital Continuous Welding

Choices of different types of welding depending on application:

Conventional Spot welding, Inert Gas Welding and 3D Orbital Continuous Welding.

Our Orbital 3D welder has a rating of 80W and general accuracy of +/-0.010″

Polishing & Sand Blasting

Polishing & Sand blasting 1.jpg)

Final touch of finish product. Brushing, Sand Blasting, Time Saving and Mirror finishes.

Final touch of finish product…. Brushing, Sand blasting, Time Saving and Mirror finishes.

Processes are handled by our skillful technicians or by in-line machine set ups.

Plating — Various Types

Plating 2.jpg)

From basic nickel or zinc plate to custom requirements, RoHS and REACH compliant.

Over the years China has been continuously raising the bar in plating industry in terms of environmental pollution, heavy metals and work place hazard and safety.

Our platers are all well set up and meeting the latest standards and regulations for both EU and local authorities.

Types of plating we provide are:

Copper base and top plate , Electro-Nickel or Electroless Nickel, Clear or Colored Zinc, Chromium , Matt or Bright Tin, Silver and Gold, Anodizing, Chemical Conversion, Passivation and Chromating, Cr-Free Conversion, electro-polishing etc.

Special custom plating or genuine formulation are available in case this is required to develop hand-in-hand with our platers.

Powder Coat & Wet Paint

Coat-to-Spec with special emphasis on cosmetic finishes including custom masking.

Coat-To-Spec with special emphasis on cosmetic finishes including custom masking — the first step of good paint quality.

Paint or powder supplies are pre-approved or designated to ensure quality and consistency.

Silk Screen & Pad Print

Silk Screen & Pad Print.jpg)

Single to multiple colors. Thorough tests and assurance on screen quality and stayfastness.

Manual or machine process , single to multiple colors.

Tight control on all steps with thorough tests and assurance on screen quality and stay fastness.

We work to PMS Pantone / NCS color scheme or to custom colors as called out.

Test Standards : Adherence test , Alcohol test and custom Endurance tests etc.

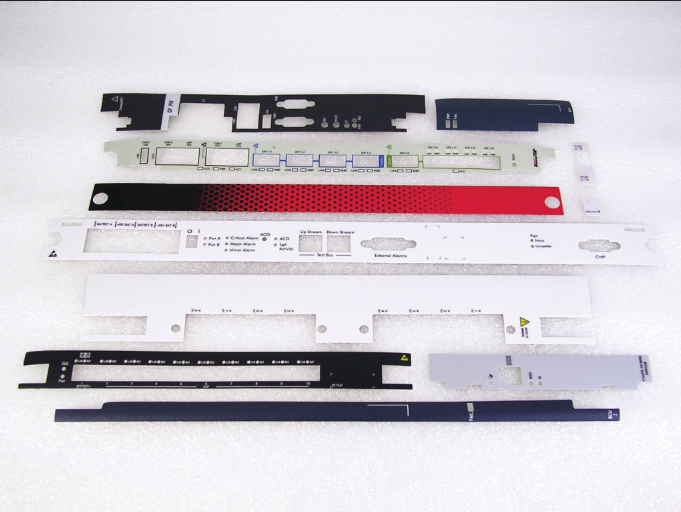

Labels & Overlays

Custom labels for front panels. In house control of quality and turn around times.

Allows in house control on quality and lead time for the finishing touch of your products.

Label Materials Available : Myler , Polycarbonate Lexan sheets , choices of textures based on requirements , designated adhesive backing.

Manufacturing Steps : Die Cutting , Silk Screening in multiple stages , window masking as required , adhesive backing applications.

Fire Rating : UL94V-0 , UL94 HR depends on choices of base material.

Color Scheme : Work to PMS Pantone / NCS or custom colors.

Test Standards : Adherence test , Alcohol test and custom Endurance tests.

XRF Spectrum Analysis

XRF Spectrum Analysis.JPG)

Analysis of material composition based on X-ray scan. Pre-alert of material non-conformance and potential RoHS issues.

Analysis of material composition base on X-Ray interferometry. Pre-alert of non-conformance and potential RoHS issues of incoming and outgoing parts.

Turret Punching.JPG)