Products

… Loading …

PCI Brackets

Witnessing the PC come of age. Supporting various PCI bracket types. Over 330M shipped.

Since then we become a major supplier of various PCI brackets and related parts for bus types like ISA, PCI and PCIe.

A total of over 330M shipped with a high reputation from our customers.

Our sophisticated equipments are tailored for fast turn prototyping as well as high volume runs.

The latest demand in this product line is in providing parts for various heat extraction designs for high power boards.

Stamp

Form

Plate

Package

Dental Cassettes

Autoclave Dental Cassettes. For various application from Exam to Surgical.

All Stainless Cases and Locks, smooth polished.

Designed for Autoclave and Dry Heat apparatus.

Tool Compartment Customization upon request.

Stamp

Form

Plate

Package

Enclosure Boxes — Sheet Metal

Supports wide range of enclosures in sizes, material and finishes.

Base Material available: Cold Rolled Steel, Pre-galvanized steel, aluminum or stainless in various stock thickness and sizes.

Manufacturing Steps: Stamping, Forming with hard tooling or Press Brakes, PEMnuts insertion, Masking of key features for Painting or Powder Coat.

Finishes: Polishing, Sand Blasting, Time Saved and Brushed, Zinc/Nickel Plate or Anodizing, Wet Paint or Powder Coating.

Silk Screen and Labeling: Silk Screen single or multi-color, Front Labels in Lexan or custom materials, different choices of finishes and Fire Ratings.

Assemblies: Final Assemblies with sub-parts or mechanicals such as triggers, switches, harnesses, light pipes.

Stamp

Form

PEM Insertion

Powder Coat

Assembly

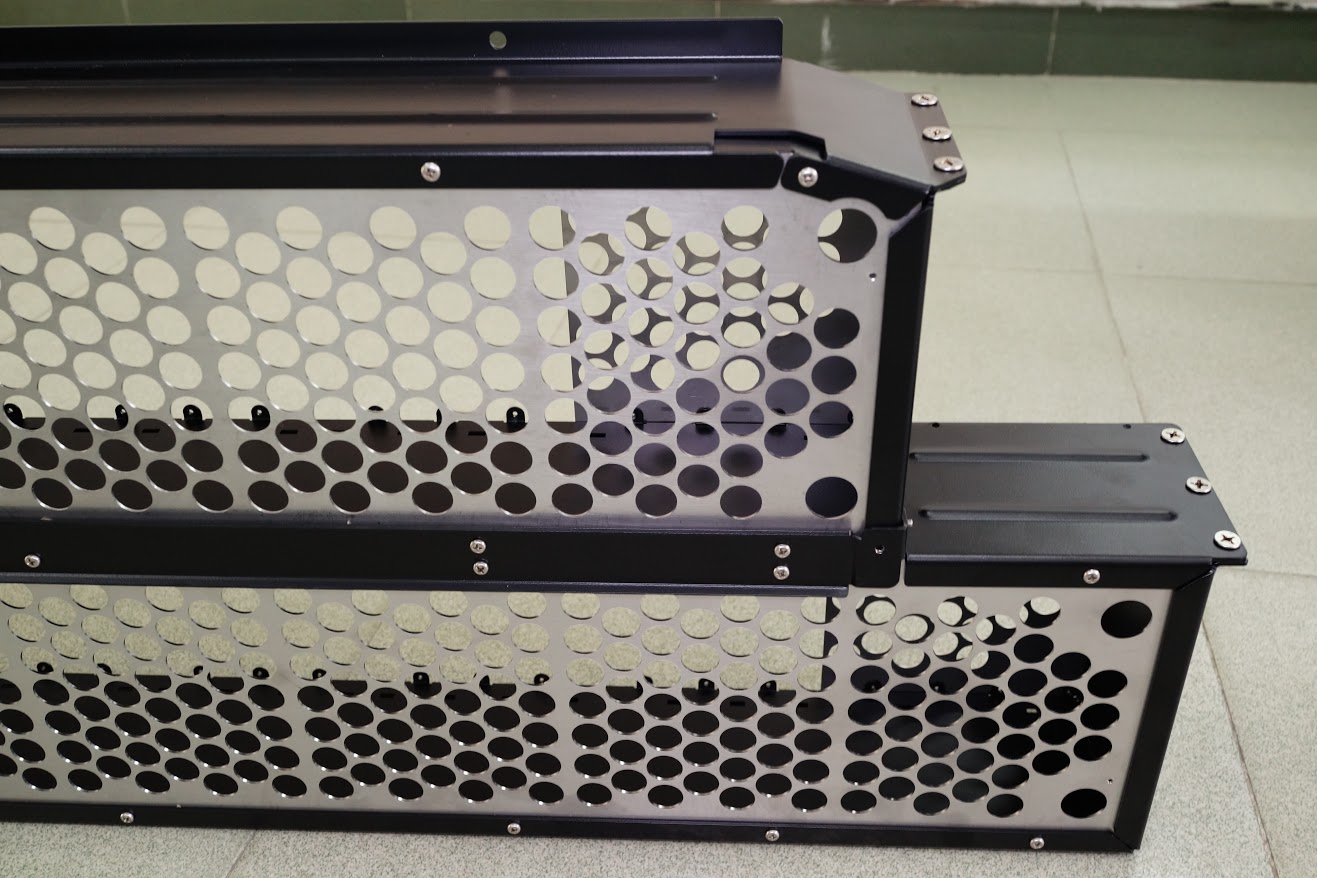

Rack Mount Enclosures and Face Plates

19″ Rack Mounts and enclosures, ATCA panels.

Base Material available: Cold Rolled Steel, Pre-galvanized steel, aluminum or stainless in various stock thickness and sizes.

Manufacturing Steps: Stamping, Forming with hard tooling or Press Brakes, PEMnuts insertion, Masking of key features for Painting or Powder Coat.

Finishes: Polishing, Sand Blasting, Time Saved and Brushed, Zinc/Nickel Plate or Anodizing, Wet Paint or Powder Coating.

Silk Screen and Labeling: Silk Screen single or multi-color, Front Labels in Lexan or custom materials, different choices of finishes and Fire Ratings.

Assemblies: Final Assemblies with sub-parts or mechanicals such as triggers, switches, harnesses, light pipes.

Stamp

Form

PEM Insertion

Powder Coat

Assembly

Extruded Parts & Heat Sinks

Custom extrusion and heat sinks.

Base Material available: 6063 or 6003 Aluminum, Cross Section diameter from minimum to 5″ in general and up to 10″ on extended versions.

Manufacturing Steps: Extrusion and Heat Treating, Sectioning, secondary operations by Stamping or CNC Machining, PEMnuts insertion.

Finishes: Polishing, Sand Blasting, Time Saved and Brushed, Chemical Conversion or Anodizing, Natural or colored.

Extrude

CNC

Polish

PEM Insertion

Plate

CNC Machined Parts

Custom panels, cPCI Panels and ejectors, heat sinks.

Base Material Suitability: Aluminum and Zinc Alloys, CRS Steel, Stainless Steel, Brass or Copper.

Machine Type: Soft programmable CNC Milling and Tapping Centre, 16000 RPM, 14 Tools, Bed Size 360 x 430 mm

Machined Tolerances: General +/- 0.002″ (+/- 0.05 mm); Controlled +/- 0.0012″ (+/- 0.03 mm), CPK Statistical Model monitored.

Production Capacity: 28 Sets, Single or Full Shift.

Typical Products: Custom panels, cPCI Panels and ejectors, heat sinks.

CNC

Die Castings — Aluminium, Zinc

Supports Aluminium and Zinc Alloy, grades Zamak 3 to Zamak 8.

Base Material Availability: Aluminum Alloys, ASTM Grades; Zinc Alloys, ZAMAK #3 to #8.

Manufacturing Steps: Die Cast (Capacity 16 to 280 Ton), secondary de-flash, CNC Machining, Post Plating, PEMnuts insertion, Masking of key features for Powder Coat as necessary.

Cast Tolerances: General, as Cast +/- 0.008″ (+/- 0.20 mm); Controlled +/- 0.002″ (+/- 0.05 mm).

Post Plating: Passivation and Chromating, Clear or Colored Zinc finishes, Electro-Nickel or Electroless Nickel, Chrome (Depends on alloy compatibility).

Typical Products: Custom panels, Appliance and Auto Parts.

Die Cast

CNC

Polish

Plate

Powder Coat

Chassis and Assemblies

500-1200 mm range frame and brackets.

Base Material available: Cold Rolled Steel, Pre-galvanized steel, aluminum or stainless in various stock thickness. Basic size ranges from 500-1200 mm.

Manufacturing Steps: CNC Turret Punch or Laser Cutting, Forming with hard tooling or Press Brakes, PEMnuts insertion, Masking of key features for Painting or Powder Coat.

Finishes: Polishing, Time Saved and Brushed, Zinc / Nickel Plate or Anodizing, Wet Paint or Powder Coating.

Assemblies: Final Assemblies with sub-parts or mechanicals such as triggers, switches, harnesses, light pipes.

Stamp

Form

PEM Insertion

Powder Coat

Assembly

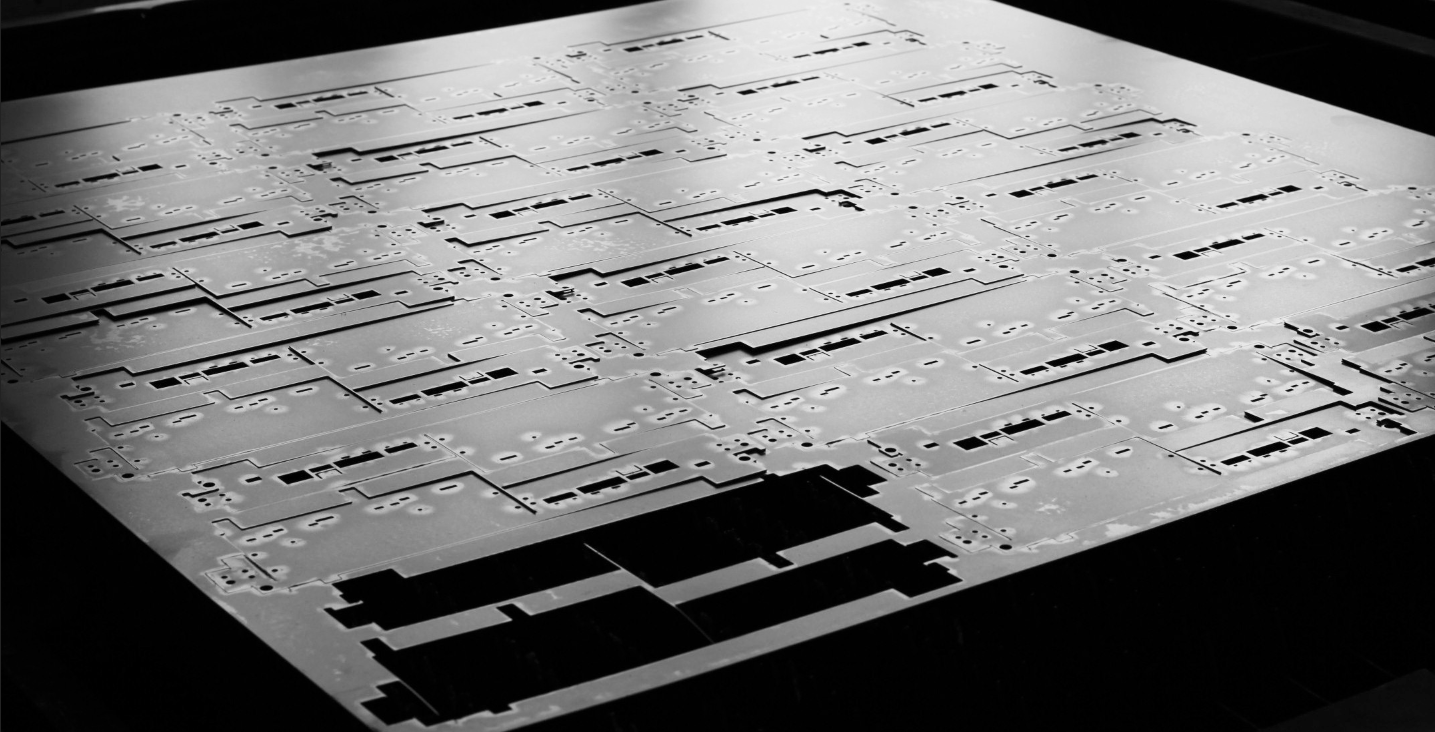

Protos — Laser Cut and CNC Parts

Short lead time possible based on soft programmable setups.

Protos are produced mainly by soft programmable CNC machines taking advantage of the shorter set up time and reduction in the number of hard tooling.

It could be Turrets, Laser Cutters, Press Brakes, CNC Millers and CNC Welders. The first three being most widely used due to their versatility.

(1)Our Turret Capability:

Soft programmable stamping suitable for proto to medium production run.

Tonnage and Bed Size: 20T, 4′ X 4′

Stamping Speed: 400 SPM average.

(2)Our Laser Capability:

Soft programmable suitable for iron, stainless and aluminum sheets.

Machine Specification: 4 KW Output Max, 5′ X 10′; Max thickness of cut: CRS / Stainless / Aluminum: 22 / 8 / 10 mm

(3)Our Press Brakes:

Soft programmable bending and forming

Machine Specification: 40 T, Bend Width 1.3 to 3.0 Meter Max.

Laser Cut

Form

Polish

PEM Insertion

Plate

Custom EMI Shields

Custom EMI shields manufactured and packaged to suit your SMT needs.

Base Material available: Pre-Tinned or Pre-galvanized steel, stainless, Brass, Nickel Silver Alloys.

Manufacturing Steps: Stamping and Form, Degrease, Packaging.

Finishes: Mostly pre-plated, could be post-plate tin, silver or gold on occasions for improved solderability.

Packaging Types: Bulk, Blister Pack, Tape and Reel for SMT Feeders.

Stamp

Form

Degrease

Tape & Reel

Packaging

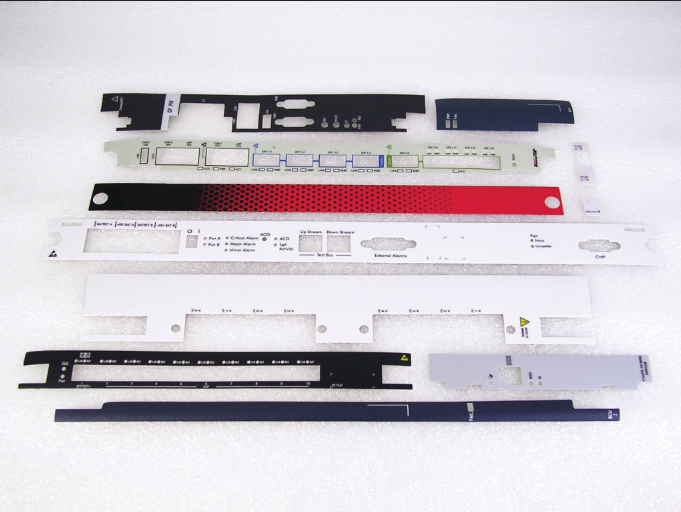

Front Panel Labels and Overlays

Allows in-house control on quality and lead time for the finishing touch on your products.

Allows in house control on quality and lead time for the finishing touch on your products.

Label Materials available: Myler, Polycarbonate Lexan sheets, choices of textures based on requirements, designated adhesive backings.

Manufacturing Steps: Die Cutting, Silk Screening in multiple stages, window masking as required, adhesive backing applications.

Fire Rating: UL94V-0, UL94 HR depends on choices of base material.

Color Scheme: Work to PMS Pantone/NCS or custom colors.

Test Standards: Adherence test, Alcohol test and custom Endurance tests.

Die Cut

Silk Screen

Masking

Backing

Electro-mechanical assemblies and sub-assemblies

One-stop solution of mechanical assemblies allowing your products to be assembled and ready to ship to your users.